+91-9751875884,+91-99423 94711 contact@bestinnovationtechnolgies.com

BEST INNOVATION

TECHNOLOGIES

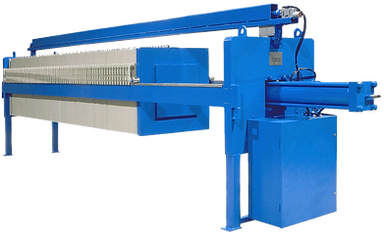

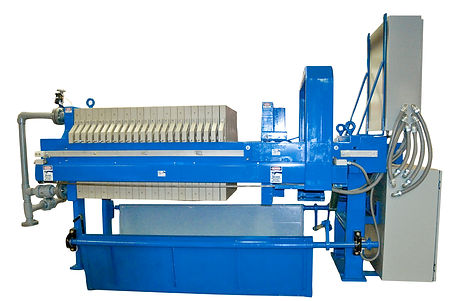

Filter Press

Efficient Solid-Liquid Separation for Industrial Processes

At Best Innovation Technologies, we provide high-performance Filter Presses designed to separate solids from liquids in wastewater, slurry, and industrial process streams. Our filter press systems deliver superior dewatering efficiency, reduce sludge volume, and optimize waste handling.

What is a Filter Press?

A Filter Press is a mechanical device that uses pressure to separate solids and liquids. The slurry is pumped into the press chambers formed by filter plates, where the liquid passes through the filter media and solids are retained, forming filter cakes for easy disposal or further processing.

Key features

• Wide range of sizes and capacities for various industrial needs

• Plates made of durable materials like polypropylene, stainless steel, or metal composites

• Manual, semi-automatic, and fully automatic operation modes

• High-pressure filtration up to 16 bar or more

• Quick cake discharge and easy maintenance

Applications

-

Textile dyeing and processing units

-

Pharma and chemical industries

-

Power plants and refineries

-

Leather tanneries and electroplating units

-

Food and beverage processing

Benefits of Our Filter Press Systems

Achieve significant reduction in sludge volume and lower disposal costs.

Produce dry, compact filter cakes for safer and easier handling.

Improve water recovery, enabling efficient recycling within your process.

Ensure reliable, low-maintenance operation with customizable system configurations.